Modular and Portable

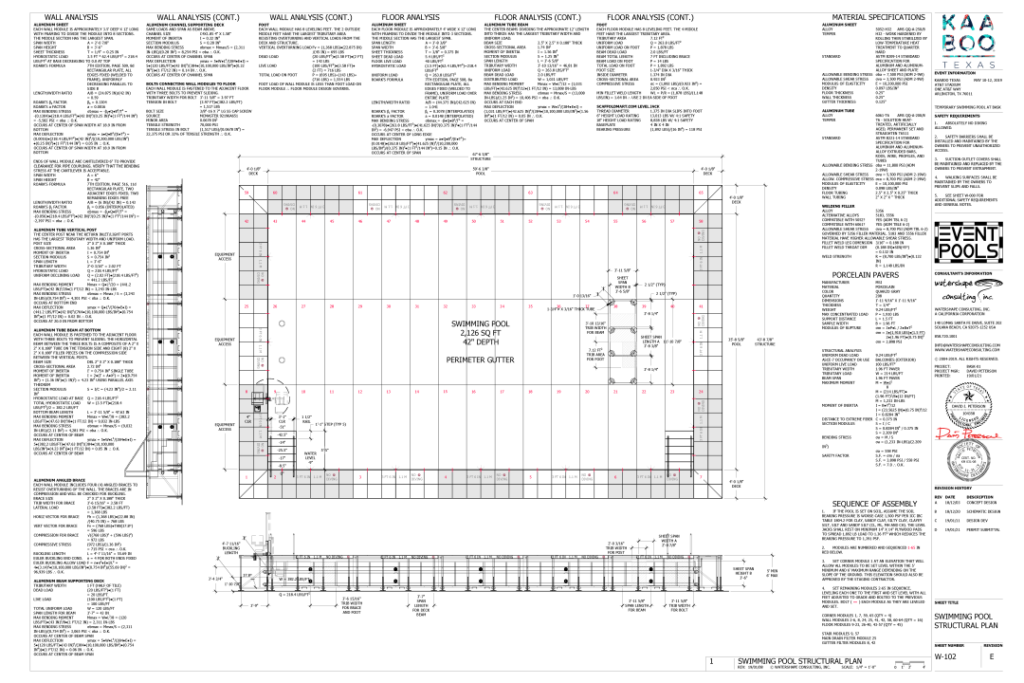

The floor is assembled using 45 welded 12′ x 4′ modules that are each leveled using 8 adjustable screw jacks. The walls are assembled using 16 welded 12′ x 4′ x 5′ high modules that are each leveled using 8 adjustable screw jacks. The 4 corner modules store the stair components during shipment which requires a pair of 53′ step-bed trailers.

State-of-the-Art Mechanical Systems

A pair of suction outlets at the floor safely conveys water to a variable speed pump, cartridge filter, and electric heater. A pair of channel drains in the perimeter gutter safely conveys water to a pair of variable speed pumps and cartridge filters. The filtered and heated water returns through 1-1/2″ stainless steel return fittings located low on each of the 16 wall modules. A chemical automation system continuously monitors and feeds chlorine and acid for pH stability 24/7.

Attention to Detail

Every aspect of this pool is custom. The suction outlets and lights utilize custom stainless steel fittings machined using computer numerical control (CNC) from 3D parts modeled in Fusion360. The stairs, handrails, and ADA lift provide safe entry and exit from the pool. The equipment includes flow meters, pressure gauges, check valves, isolation valves, and special twist-lock compression fittings to connect the 192′ long return loop of 3″ Schedule 80 PVC pipe.

Water Quality

Although it isn’t required by the health department, we engineered the filtration system to operate at a 4 hour turnover or better. We can actually operate at a 2.8 hour turnover if desired. This is to ensure that we can maintain the water quality even if the pool is heavily loaded. The chemistry is continually monitored and controlled using an ORP/pH controller. The water is also heated and floating bubble covers are used when the pool is closed to retain heat.

Plug & Play

Single-phase 240V power is connected at a single point for all 4 pumps, 16 lights, 1 controller, 1 autofill, and 1 automated chlorine and acid monitoring and control system. A 1″ PEX potable water line is connected for automatic filling of the pool and on-demand operation of the ADA lift. A 2″ drain to waste is connected via cam-lock.